It’s a truism that space exploration and deployment has always been among the earliest of adopters when it comes to new technology. So just as the world was sitting up and taking notice in 2016 when a Vulcan 2 3D printer was used to create homes in Latin America – at a cost of only $6,000 per building – the space industry was quietly getting on with its own adaptations of the technology. More than $9bn of venture capital was finding its way to Silicon Valley pioneers specialising in 3D printing processes for aeronautical and space vehicle componentry.

It’s a truism that space exploration and deployment has always been among the earliest of adopters when it comes to new technology. So just as the world was sitting up and taking notice in 2016 when a Vulcan 2 3D printer was used to create homes in Latin America – at a cost of only $6,000 per building – the space industry was quietly getting on with its own adaptations of the technology. More than $9bn of venture capital was finding its way to Silicon Valley pioneers specialising in 3D printing processes for aeronautical and space vehicle componentry.

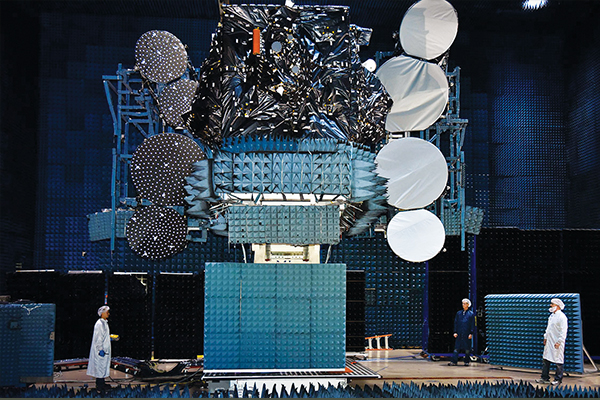

Since then, the pace of change has been remarkable, with even industry titans such as Boeing progressing from traditional multi-component assembly to additive manufacturing on large-scale satellite projects. When a Boeing satellite was launched in May 2019 with arguably the first-ever 3D printed metal antenna, it showed that a major sea-change had taken place, and the development of one-of-a-kind, custom-made designs had become the new normal.

So what exactly are the benefits of additive manufacturing (AM), and what are the catalysts for the rapidly accelerating take-up of its advancing technologies in the satellite sector?

First things first. AM is used primarily because it’s cheaper than conventional engineering assembly, right?

“That’s a loaded question,” says Janos Opra, CEO of Optisys, a metal additive manufacturing specialist focusing on 3D metal printing of commercial and military antennas and RF components. “In reality, it’s important to compare like for like, oranges with oranges. In general terms, 3D printing would be four times more expensive. If you are only carving out a single piece of aluminium, that process is very cheap and you don’t need to go down the 3D printing route. The 3D printing machines are very expensive and you wouldn’t want to use them for a more simple, straightforward process.

“That’s a loaded question,” says Janos Opra, CEO of Optisys, a metal additive manufacturing specialist focusing on 3D metal printing of commercial and military antennas and RF components. “In reality, it’s important to compare like for like, oranges with oranges. In general terms, 3D printing would be four times more expensive. If you are only carving out a single piece of aluminium, that process is very cheap and you don’t need to go down the 3D printing route. The 3D printing machines are very expensive and you wouldn’t want to use them for a more simple, straightforward process.

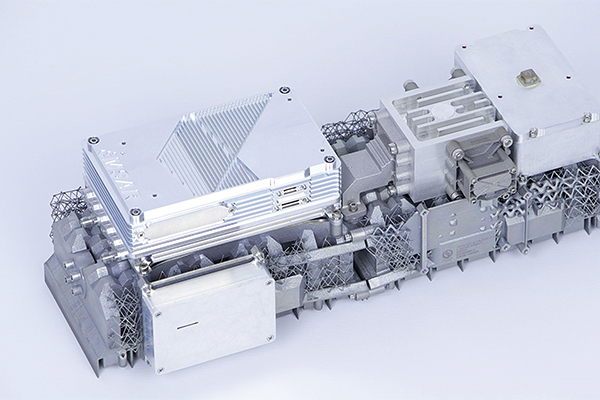

“It’s with the more complicated projects that 3D printing comes into its own. If you are adding a lot of new elements into the mix, it starts to be cheaper. Adding extra features with conventional processes can mean completely rethinking your assembly line, whereas with AM, you can simply make one change to the software blueprint and everything is taken care of in one step.”

Opra’s comments are echoed clearly by Ole Geisen, Head of Engineering Services for Additive Manufacturing for Siemens, one of the largest industrial technology companies in the world. He believes that in most cases today, the component cost is not reduced by AM.

“In sectors like space, aerospace and energy, many customers are more interested in the benefits generated by operating an optimised component, which is why these industries were among the early adopters of the process. So performance is usually the main concern when considering AM, and staying cost-neutral is a common requirement. Other important advantages of AM that customers usually try to leverage are the improved lead time or the possibility to source components on demand, which can lead to indirect cost savings.”

The reality is that performance enhancement, not cost-saving for its own sake, is the core USP of AM. This is never truer than in relation to one critical feature: weight. Just as the astronaut Neil Armstrong called water “the gold of space”, weight-saving is the Eldorado of satellite manufacture.

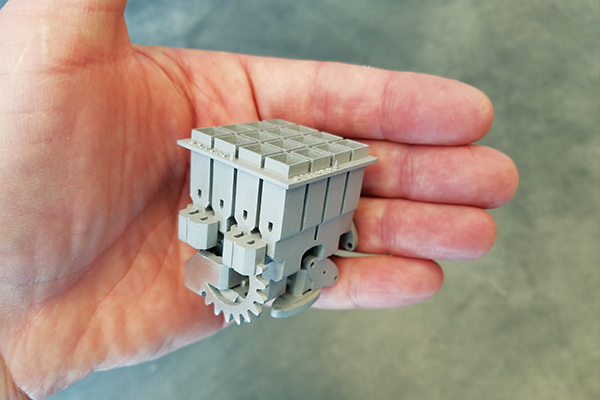

“In modular systems,” continues Opra, “you have very heavy elements which may weigh 15-16 pounds, but with our processes, you are replacing these with pieces that may only weigh a few ounces. We can also add in extra elements within a week – for example, adding an additional filter and so on. The weight reduction can be 10-100 times! Plus, the beauty of the AM process is that we can specify the performance criteria the client requires and then create a programme to make the structure as thin and lightweight as possible, to save on the manufacturing cost. We add in just enough material to withstand the stress required.”

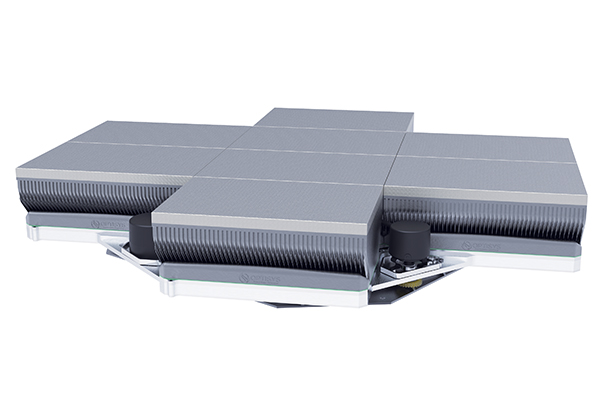

Geisen concurs. “Even with simple topology optimisation, it is usually possible to reduce the weight of, say, a machined bracket by around 20% while improving the stiffness. Depending on the quality of the initial design and the possibilities to integrate multiple parts into one, the weight reduction can be higher still.”

Geisen concurs. “Even with simple topology optimisation, it is usually possible to reduce the weight of, say, a machined bracket by around 20% while improving the stiffness. Depending on the quality of the initial design and the possibilities to integrate multiple parts into one, the weight reduction can be higher still.”

This weight-saving aspect is particularly important, given that the type of AM used in space applications is metal-based AM, not the plastic or acrylic styles of 3D printing that might first come to mind based on an awareness of domestic or construction usage.

“Metal is required for most aerospace applications,” Opra explains. “Aerospace companies require a strong material – plastics can’t handle the extreme temperature variations. For antenna purposes, the best material is aluminium, because it has the highest signal conductivity (although in reality, gold is the best of all – but just imagine the weight. Not to mention the cost!). Plastics will often be used for prototyping, although they cannot generally be used in the finished aerospace application.

“There are many different processes, and each one is better suited for a different purpose. Some are better for making very large structures, some are better for making multiple structures. At Optisys, we use powder bed fusion. This is a very refined process of metal AM and gives the finest resolution, which you need for antennae.”

This same process is used by Siemens.

“We have been among the very early adopters of AM, starting to use laser powder bed fusion in 2006 and collaborating with several printer OEMs to drive the technology from laboratory to industrial applications. At the same time, we have worked on the software solutions necessary to turn all the creativity of our designers into 3D-printed parts,” says Geisen.

What about the actual composition of the alloys most frequently used? Geisen elaborates: “It’s interesting to note that traditionally, the chemical composition of AM materials didn’t really differ from conventional alloys, and this was mainly to improve the acceptance of the technology. But even with the same chemical composition, the printed material can behave differently due to its microstructure. Lately, we have seen a growing number of alloys designed specifically for AM, with better processability and performance. This is a very positive development, as it shows the increased confidence in the technology.

“AM is here to stay and not just a temporary trend, so investing in pure AM materials makes perfect sense.”

For both Geisen and Opra, metal 3D printing is enabling both companies to support their clients’ varying space ambitions. Opra says Optisys went directly to metal 3D printing when it started.

For both Geisen and Opra, metal 3D printing is enabling both companies to support their clients’ varying space ambitions. Opra says Optisys went directly to metal 3D printing when it started.

“That’s why, four years ago, we started the company. No-one else was doing this. Then, within a month of launching the business, we launched the first design, and now we are building up a large library of designs.”

Geisen says Siemens’ role in the space industry is to support customers by creating designs that fully use the potential of metal AM. “We then print the parts at the highest possible quality and provide expertise in qualification processes. Our partners are pioneering new satellite concepts – we help them to successfully implement AM on that journey.”

Similarly, the early trend of using AM to replicate traditional assembly features has given way to the power of being able to make purpose-made parts that offer new levels of performance and technical quality. AM is also very quick so it’s a brilliant solution for prototyping.

Opra explains: “3D printing allows for quick functional prototypes and can create objects a regular machining, brazing or casting process cannot. For example, curved internal features, air cooling features, lattice structures for decreasing weight, etc. But the reality is, every type of technology has its advantages and its problems. We picked AM because it gave us a new option – remember, antennas had been created the same way for the last 30-40 years. AM allows you to make very compact integrated structures, things that could never have been manufactured in the past because they would have needed 30 separate pieces and processes.

“It’s also important to remember that AM has its own unique design process, and time and again we found we had to start the design process from scratch. Whatever designs you liked in the past don’t work anymore. You may have designed it in a certain way to get certain results, but these criteria just don’t exist anymore.”

This step into the unknown can involve complex benchmarking tests to demonstrate that AM structures have the required compliance. Geisen reviews the typical timeline: “First, a machine and a process need to be selected and fine-tuned to guarantee reproducibility. Numerous test bars are then printed to analyse the material properties in a wide range of mechanical tests, for example, tensile and fatigue tests. The acquired data allows design engineers to optimise the shape of the structure in various software tools. After the print, multiple quality tests can be performed to guarantee conformity. This can include dimensional tests, surface roughness measurements or CT scans for critical structures.”

This step into the unknown can involve complex benchmarking tests to demonstrate that AM structures have the required compliance. Geisen reviews the typical timeline: “First, a machine and a process need to be selected and fine-tuned to guarantee reproducibility. Numerous test bars are then printed to analyse the material properties in a wide range of mechanical tests, for example, tensile and fatigue tests. The acquired data allows design engineers to optimise the shape of the structure in various software tools. After the print, multiple quality tests can be performed to guarantee conformity. This can include dimensional tests, surface roughness measurements or CT scans for critical structures.”

In fact, the R&D process can be extremely complex when it comes to creating AM componentry and structures. Geisen continues: “If a customer component needs to go through full certification, the material data generation alone can last half a year. Adding the external certification process, we see programmes that easily run for a year or even more. The creative design process and a validation build job are only a small portion of the total development lead time – most of the time is spent on the qualification. While this can sometimes be frustrating, we strongly believe that the introduction of new standards and more cross-industry collaborations will help reduce the AM development times.”

Once the compliance protocols are established, the manufacture is not only very quick but virtually free of waste and capable of completely raising the bar in terms of sheer accuracy.

Opra says: “We don’t have to have things on the shelf which aren’t needed – all we need in stock is powdered aluminium. A traditional system can take 9-12 months to design. But we are down to two-three months, and we believe we can cut this down to several weeks in the future. The design is much faster, the manufacturing is much faster and the cost is much cheaper. Moreover, the likelihood of error is much less – there are fewer things that can be broken along the way.

“Once the 3D printers are in process, they are very accurate unless the machine has a malfunction. Of course, there can still be human error afterwards; for example, if someone drops the piece or breaks it while taking it out of the machine!”

In many cases, technological advances are making earlier aspirations a reality. “The key trends I see now are not new,” says Geisen. “Functional integration and light weighting still have huge potential for satellite applications. Two of the main benefits in designing AM parts are the possibility to combine multiple parts into one (potentially with improved functionality) and topology optimisation – only putting material where it’s really needed. We still see plenty of opportunities that can be covered by these approaches. Current developments like multi-material AM or a combination of different AM technologies will allow us to identify further applications in the space industry over the next couple of years.”

In many cases, technological advances are making earlier aspirations a reality. “The key trends I see now are not new,” says Geisen. “Functional integration and light weighting still have huge potential for satellite applications. Two of the main benefits in designing AM parts are the possibility to combine multiple parts into one (potentially with improved functionality) and topology optimisation – only putting material where it’s really needed. We still see plenty of opportunities that can be covered by these approaches. Current developments like multi-material AM or a combination of different AM technologies will allow us to identify further applications in the space industry over the next couple of years.”

Indeed, Geisen believes that, even with larger satellites, AM is now at the stage where it is actually enhancing the overall technical performance of the satellite.

“Light weighting, increased stiffness or functional integration using AM all can lead to a tangible performance improvement of a satellite today. Yet conversely, at the stage we are at, I do also see some limitations for using AM in satellite assembly.

“For example, a first and still very real challenge is the lack of education around AM. Even for companies that have been doing AM for several years, having a highly educated core of designers and development engineers is not enough to turn a prototype into a successful serial part. All the stakeholders in an organisation, such as quality departments, strategic purchasing, management, etc, need to have a solid understanding of AM to complete a qualification.

“A second challenge we are always facing in highly regulated industries is the time and money needed for full qualification and certification of a new component, as described above. The certification bodies often have limited experience with the new technology and do not have pre-defined requirements, leaving it up to the user to make reasonable proposals. Really, the international standards for AM clearly need to catch up with the needs of the industry today. But we have seen some very positive developments recently, for example, the cooperation between ASTM and ISO.”

In terms of the technology platforms available, it is, of course, the case that, as Opra explains, “Every few years the machines have a major improvement. Our Holy Grail is to find a machine that can do everything better ¬ to find a machine that lifts our performance, reduces our costs and lessens our lead times, etc. From our point of view, certain providers stand out in the sector; companies like Eos, Concept Laser and SLM are the leading manufacturer platforms.”

In terms of the technology platforms available, it is, of course, the case that, as Opra explains, “Every few years the machines have a major improvement. Our Holy Grail is to find a machine that can do everything better ¬ to find a machine that lifts our performance, reduces our costs and lessens our lead times, etc. From our point of view, certain providers stand out in the sector; companies like Eos, Concept Laser and SLM are the leading manufacturer platforms.”

The actual level of AI in the printing process has not necessarily changed very much, though, as Geisen points out. “Today, the use of AI in the printing process is still very limited. This is why at Siemens, in cooperation with our software division, we have developed a machine-learning tool to analyse the vast amounts of data generated during the monitoring of long build jobs. In addition, we’re participating in research projects that target the use of AI to optimise process parameters and accelerate development programmes.

“For a wider implementation in the quality assurance of serial components, these types of AI-driven software tools need to mature, but it’s only a matter of time until we see them in the AM market. That’s when we’ll be able to deliver the next quantum leap in terms of performance capability as applied in the satellite sector.”

Add Comment