Satcube, a European technology company that develops lightweight terminals to provide satellite broadband, is building a new facility for the mass production of satellite terminals, both for existing product verticals and new ventures for LEO and vehicular applications.

Satcube, a European technology company that develops lightweight terminals to provide satellite broadband, is building a new facility for the mass production of satellite terminals, both for existing product verticals and new ventures for LEO and vehicular applications.

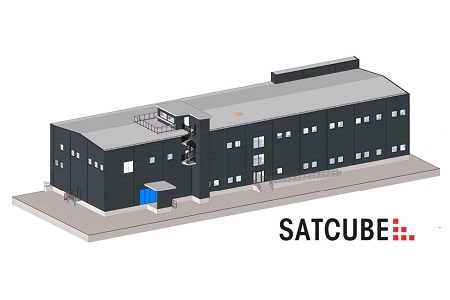

The new facility is replacing the existing production facility in Karlstad.

The new state-of-the-art facility will be completed on July 1, with a production timeline aimed at mid-August.

Harnessing core CSR principles, the new facility will feature automated and semi-automated production founded on Green Lean Digital and Agile processes. Combining these forward-leaning standards with an increased level of production line automation will enable Satcube to quickly scale up manufacturing to accommodate high volume terminals orders – while simultaneously keeping production costs low in a winning scenario for customers and the company’s long-term strategy.

Jakob Kallmér, CEO of Satcube, said: “Satcube achieved an impressive 140% increase in revenue from 2021 to 2022 and is already serving major NGOs, media brands, military, and governments agencies. Due to significantly increased demand for Satcube products, we have nearly reached maximum production capacity in existing facilities.”

Kallmér added: “With a nearly three-fold increase in production available at our new facility, Satcube will be able to deliver substantial new volumes while tapping a highly automated production line to shorten the time between order and delivery. The new, highly agile setup will enable Satcube to both rapidly and seamlessly establish production of new products and deliver on custom orders with specialised requirements.”

Satcube’s already established local production principles are well aligned with supporting a growing regional EU supply chain, tapping local technology, research, development, employment opportunities, and production.

Henrik Strandén, COO & Production Manager at Satcube, stated: “When manufacturing complex high-tech products that require expert engineering, it is without a double a major advantage to offer close proximity between development and manufacturing departments.”

Strandén noted: “This hands-on, integral, close approach and focus on teamwork leads to higher quality products and shorter time to market for new products. There are far more benefits to having in-house manufacturing, including full control of supply chain stability, waste management, working conditions and safety standards. Through our strategy, we are able to realize a cost-efficient and reliable supply chain for our customers.”

Spokespersons from Satcube will be on-site at the Satellite 2023 expo in Washington to share details on its local sourcing strategy and growth plans. In addition, demonstrations of the light-weight, portable Satcube Ku satellite terminal will be available during the expo.

Stand 1760

Add Comment